HS-1064P Unsaturated Polyester Resin Characteristics and main uses: HS-1064P resin is a kind of unsaturated polyester resin specially used for making flame retardant light transmitting FRP lighting boards, which can reach the requirement of first class flame retardant with good infiltration of glass fibre, good light transmittance and weathering, excellent mechanical strength and flame retardant property. It is suitable for machine or hand-laid moulding of light-emitting boards (tiles). This product complies with the EU ROHS directive on lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBBs) and polybrominated diphenyl ethers (PBDEs). Liquid resin technical indicators: | Item | Unit | Specification | Test Method |

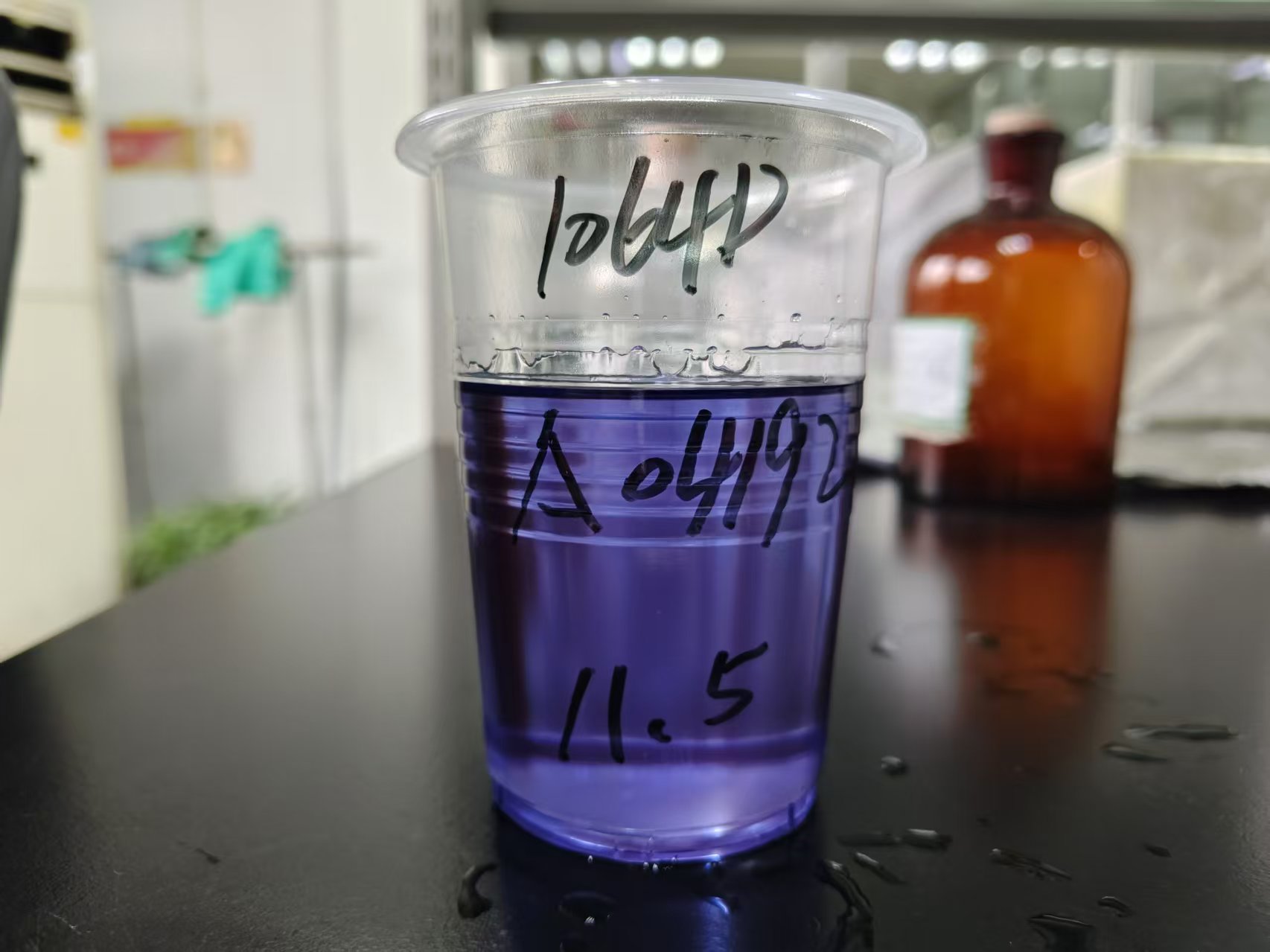

| Appearance | --- | Purple-red transparent liquid | GB/T 8237.6.1.1 |

| Viscosity | 25ºC , cp | 180-260 | GB/T 7193.4.1 |

| SPI-GT | min. | 0.5-2.0 | GB/T 7193.4.4 |

| SPI-CT | min. | 2.0-4.0 | GB/T 7193.4.4 |

| SPI-PET | ºC | 185-220 | GB/T 7193.4.4 |

| Solid Ccontent | % | 60-70 | GB/T 2895 |

Note: When testing SPI curing properties, the curing system is: accelerator KC: 2%; curing agent M-50: 1.2%.

Physical properties of Casting(for reference only):

| Item | Unit | Measured Value | Test Method |

| Tensile Strength | MPa | 55 | GB/T 2568 |

| Bending Strength | MPa | 90 | GB/T 2570 |

| Elongation at Break | % | 3.5 | GB/T 2568 |

| Heat Distortion Temperature | ºC | 60 | GB/T 1634 |

| Oxygen Index | % | 30 | GB/T 3854 |

Note: 1) The casting system sample method is implemented according to GB/T 8237. Curing system: accelerator (0.6% Co-Naph): 2%, curing agent (AKZO M-50): 2%; (2) Post-curing treatment of casting body: room temperature×24 hours+60ºC×3 hours+100ºC×2 hours.

Precautions:

Transportation should be in accordance with the provisions of the State Council's 'Regulations on the Safe Management of Dangerous Chemicals', Chapter V, Transportation and Handling of Dangerous Chemical Substances. The product should be stored in a cool place under 25ºC, avoid fire, isolate heat source, and keep it sealed to prevent moisture intrusion and volatilisation of monomer. Shelf life is 3 months when stored under 25ºC.