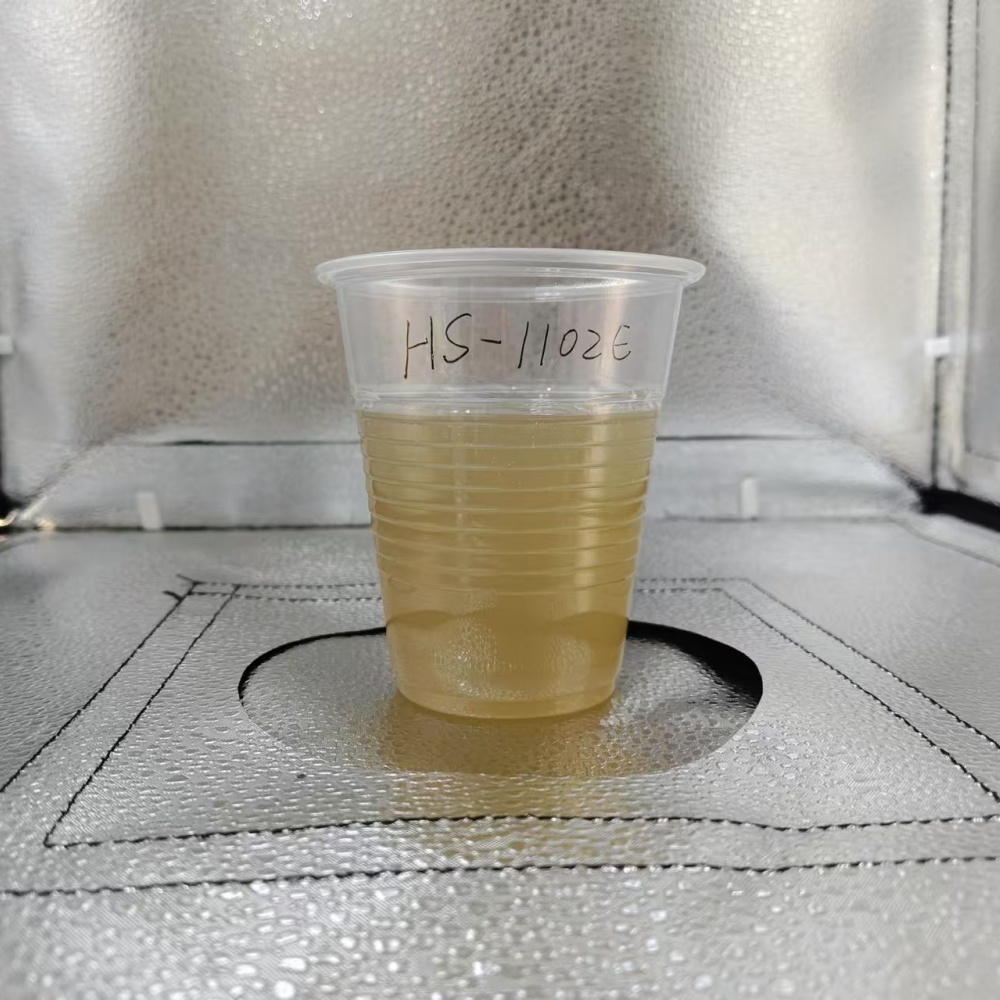

HS-1102E Unsaturated Polyester Resin

n Principal Properties & Application:

The HS-1102E series is an unsaturated polyester resin with medium reactivity, pre-accelerated, thixotropic, and good fiberglass wetting properties. It has excellent processing performance, smooth curing speed, and low shrinkage. The resin exhibits outstanding water resistance and good overall mechanical properties, making it suitable for hand lay-up/spray-up processes in the production of FRP products such as cockpit covers, automotive parts, and cooling towers.

This product complies with the EU RoHS directive concerning the content standards for lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls, and polybrominated diphenyl ethers.

n Specifications of liquid resin:

Item | Unit | Standard Requirements | Test Method |

Appearance | -- | Opaque liquid | GB/T 8237.6.1.1 |

Viscosity | 25℃, cP | 200-900 | GB/T 7193.4.1 |

Gel Time | 25℃, min | 10-80 | GB/T 7193.4.6 |

Solid Content | % | 60-68 | GB/T 7193.4.3 |

Note: The curing system during the gel time test is: Curing agent AKZO M-50: 1%.

n Physical properties of Casting(for reference only):

Item | Unit | Test Value | Test Method |

Tensile strength | MPa | 58 | GB/T 2568 |

Tensile Modulus | MPa | 2800 | GB/T 2568 |

Elongation at Break | % | 2.0 | GB/T 2568 |

Flexural Strength | MPa | 100 | GB/T 2570 |

Flexural Modulus | MPa | 3368 | TB/T 2570 |

Impact Toughness | KJ/m² | 6.3 | GB/T 2571 |

HDT | ℃ | 62 | GB/T 1634 |

Barcol Hardness | -- | 40 | GB/T 3854 |

Note:

1). The casting body preparation method follows GB/T 8237-2005. Curing system: AKZO M-50: 1.5%.

2). Post-curing system for the casting body: Room temperature (24 h) + 60°C (3 h) + 100°C (2 h).

n Precautions:

· Users should select the appropriate type of resin based on specific environmental conditions and process requirements.

· The HS-1102E series is a thixotropic resin. During storage, the thixotropic agent may settle, so it is recommended to gently stir before use to re-disperse it evenly.

· The product should be stored in a cool place below 25°C, away from sources of ignition and heat (such as direct sunlight or steam), and the container should be sealed to prevent moisture and monomer evaporation. The shelf life at temperatures below 25°C is 3 months.